How to Choose the Right CNC Machining Service Provider for Your Project?

Views: 0 Author: Site Editor Publish Time: 2025-07-18 Origin: Site

When you pick the right cnc machining service providers, look at their skills, experience, and how they check quality. Check if they have certifications, talk well, have good prices, and finish work on time. You need a cnc machining provider that fits your project’s material, tolerances, and industry rules. A cnc machining service with good skills helps you not make expensive mistakes. Always look at cnc machining choices from different cnc machine shop teams. Use a checklist to help you pick the best cnc machining service for your needs.

Key Takeaways

Pick a CNC machining provider with the right skills. Make sure they have experience and certifications. They should match your project’s materials and needs. They must also meet your tolerances and industry rules.

Check what machines the provider uses. See what materials they can work with. Make sure they can make both prototypes and big orders.

Look for strong quality checks. The provider should have certifications and do careful inspections. They need a good record for making reliable and exact parts.

Choose a provider who answers you fast. They should give good help after you buy. They must be able to handle changes in your order or deadlines.

Think about the provider’s reputation and how they keep data safe. Make sure they can grow with your business. This helps you build a long and trusted partnership.

Project Requirements

Materials

Picking the right material is important for your project. Different jobs need different materials. Each industry uses what works best for them. For example, these fields use certain materials:

Stainless steel is strong and lasts long. It is used for things like surgical tools and airplane parts.

Aluminum alloys are light and easy to shape. They are found in cars, planes, and medical tools.

Titanium is tough and does not rust. It is safe for the body and used for implants and plane frames.

Carbon steel is very hard and strong. It is good for car parts and machines.

Brass and copper are used for medical parts and electrical pieces.

Here is a table that shows some common materials. It also tells you what they are good at and where they are used:

| Material Type | Key Properties | Common Industry Applications |

|---|---|---|

| Stainless Steel | Corrosion resistant, strong, wear resistant | Medical devices, aerospace components |

| Aluminum Alloys | Lightweight, strong, machinable, corrosion resistant | Aerospace frames, automotive parts, medical devices |

| Titanium | Strong, corrosion resistant, biocompatible | Medical implants, aerospace frames |

| Carbon Steel | Durable, hard, abrasion resistant | Heavy-duty automotive parts, machinery |

| Brass | Machinable, corrosion resistant, conductive | Medical components, electrical fittings |

| Copper | Thermal/electrical conductivity | Heat sinks, electrical components |

Tongyu can work with both metals and plastics. This means you can get the right material for any job.

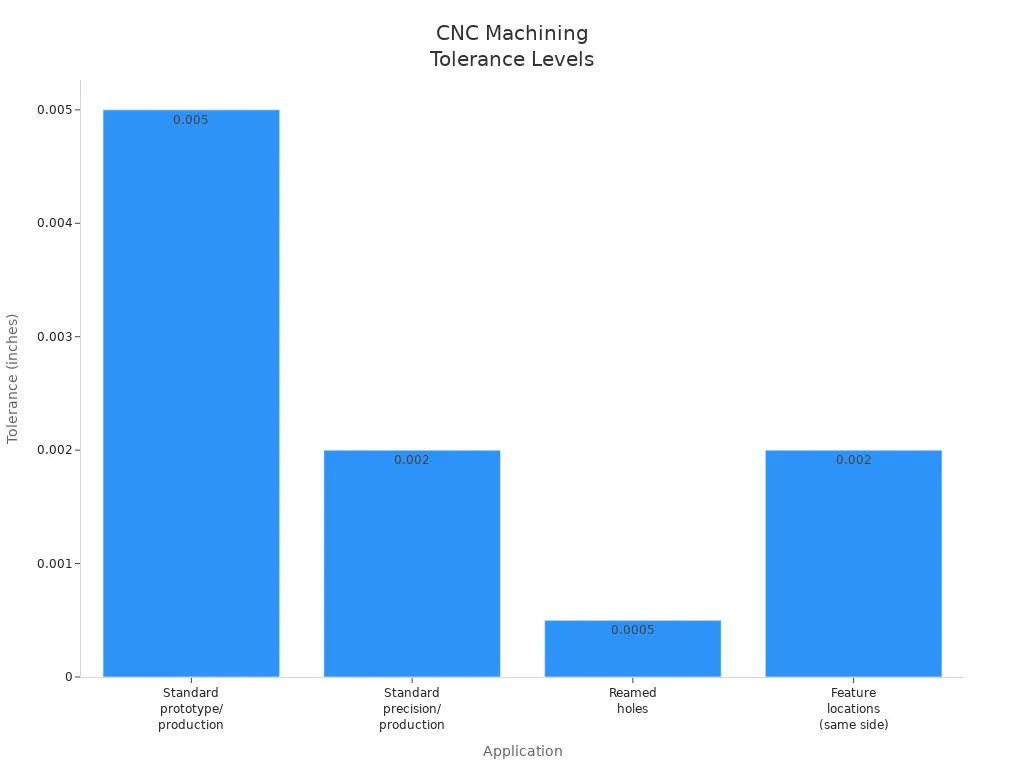

Tolerances

You need to know how exact your parts must be. Some jobs, like in aerospace or medical, need very tight tolerances. This means the size must be almost perfect, like ±0.001 inches or even less. This helps parts fit right and work safely. For example, implants and airplane parts need to be measured very carefully.

Tongyu can make parts with tight tolerances. They can do ±0.005mm for turning and ±0.01mm for milling. This is good for projects that need high accuracy.

Volume

Think about how many parts you need. Some projects just need a few test pieces. Others need thousands for big orders. Here is a simple guide:

Prototyping means making 1–10 pieces. This is good for trying out ideas.

Low volume is 10–100 pieces. This is for small batches or test runs.

Mass production is 100–10,000+ pieces. This is for making lots of parts.

Tongyu can help with both small and big orders. You can order more as your project grows.

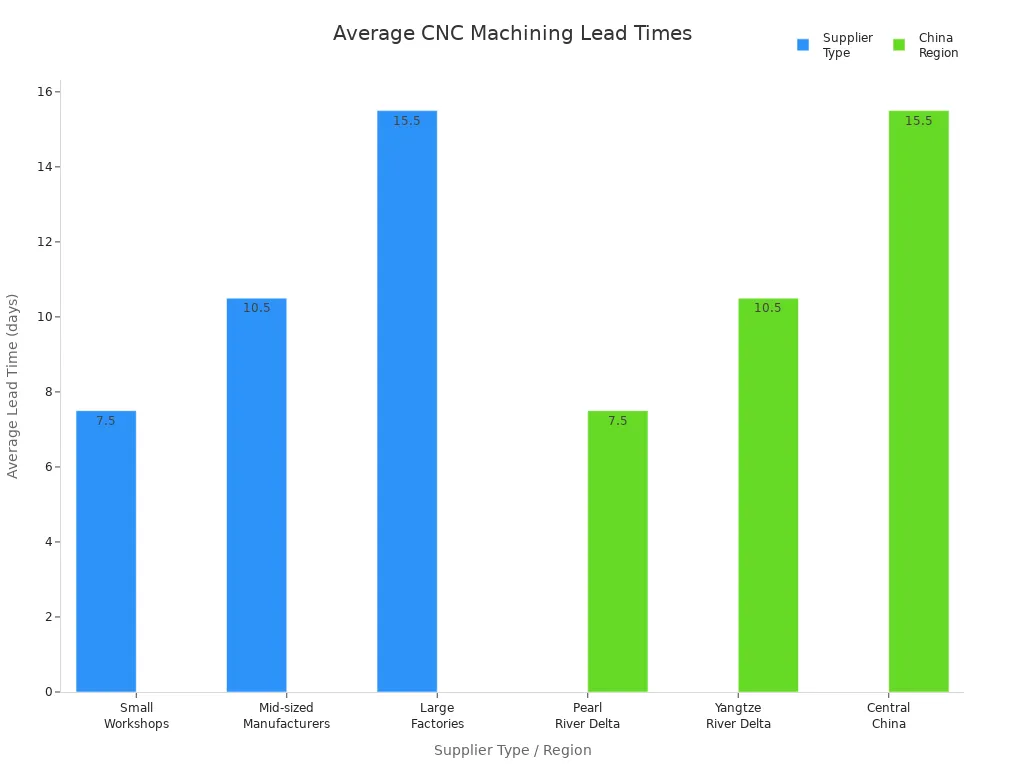

Deadlines

You should plan when you need your parts. How long it takes depends on how many you want and how hard they are to make. For example:

| Order Type | Volume Range | Average Lead Time (Standard Orders) |

|---|---|---|

| Prototype | 1–10 pcs | 3–7 working days |

| Low Volume | 10–100 pcs | 7–15 working days |

| Mass Production | 100–10,000+ pcs | 15–45+ working days |

If you need parts fast, some cnc machining services, like Tongyu, can work quicker. Always check if your provider can rush your order when you need it soon.

Experience & Expertise

Industry Focus

You want a cnc machining provider who knows your industry. If they have worked in your field, they will do a better job. For example, if you need car, plane, or medical parts, pick someone who has made these before. This means they know the rules, materials, and sizes you need.

When a cnc machining supplier has industry experience, they make good parts. Skilled workers use the right machines and tools for your project. They follow strict rules and check every part with special tools like Coordinate Measuring Machines (CMMs). They also use software and methods to keep all parts the same. This helps your parts fit and work well.

Tongyu has lots of experience in cars, planes, and medical jobs. Their team can handle hard work, like engine mounts, flight brackets, or surgical tools. They know what each field needs and follow the right steps.

Tip: Always ask if your cnc machining provider has worked in your industry before. This can save you time and help you avoid mistakes.

Track Record

A good track record means you can trust your provider. Look for companies that have done well in your field. You can read reviews, ask for examples, or get references. A good provider will tell you about past jobs and how they fixed problems.

Certifications show a provider cares about quality. Here are some important certifications and what they mean:

| Certification | Industry Focus | Key Requirements and Focus Areas | Applicability and Importance |

|---|---|---|---|

| ISO 9001 | General Quality Management (including Automotive) | Quality system, customer satisfaction, process consistency, audits, risk-based thinking | Used in many industries; ensures reliable quality, important for automotive manufacturing |

| AS9100 | Aerospace and Defense | Extra rules for aerospace, risk management, traceability, supplier control, design checks | Needed for aerospace and defense; ensures safety and meets strict standards |

| ISO 13485 | Medical Devices | Focus on medical device rules, risk management, traceability, strong documentation | Needed for medical devices; ensures safety and meets tough health rules |

Tongyu has all these certifications. They meet IATF 16949 for cars, AS9100 for planes, and ISO 13485 for medical devices. This means you get parts that meet the highest standards.

A provider with a good track record and the right certifications gives you peace of mind. You know your project is safe.

Technical Capabilities

CNC Machining Services

You want a cnc machining service that can do many things. This helps you finish your project, even if it is hard or easy. Top cnc machining companies, like Tongyu, offer many cnc machining services. Some of these are:

CNC turning makes things like shafts, bushings, and connectors.

CNC milling shapes parts like housings, brackets, and gears.

Stamping is used for electrical contacts, springs, and washers.

Sheet metal fabrication builds enclosures, panels, and racks.

Look at this table to see how top companies compare:

| Company Name | Advanced CNC Capabilities | Key Technologies & Services | Industries Served | Certifications & Quality Factors |

|---|---|---|---|---|

| Tongyu | Turning, milling, stamping, sheet metal | Multi-axis, tight tolerances, rapid prototyping | Automotive, aerospace, medical | ISO 9001, IATF 16949, AS9100, ISO 13485 |

| Asquare Parts Inc. | Precision CNC machining, aluminum machining | Prototyping, small-batch, bulk production | Automotive, trailer parts | Quick lead times, hands-on customer service |

| Fictiv | CNC milling, turning, anodizing, polishing | Digital manufacturing integration, CAD-to-quote system | Various high-precision parts | High-quality inspection, instant quotes |

| Xometry | Milling, turning, EDM, 5-axis machining | AI-powered platform, 3D printing, sheet metal fabrication | Aerospace, defense, automotive | Wide material range, quality assurance |

| Protolabs | 3-axis and 5-axis milling, turning | Rapid prototyping, on-demand production | Medical, aerospace, electronics | Fast turnaround, scalability |

You get more choices if your cnc machining service works with metals and plastics. Tongyu can use materials like aluminum, stainless steel, titanium, brass, PEEK, nylon, and Delrin. This means you can use one cnc machining service for many jobs.

Note: New cnc machining services now have 5-axis machining, multi-tasking machines, and additive manufacturing. These tools help you get tricky parts faster and with better accuracy.

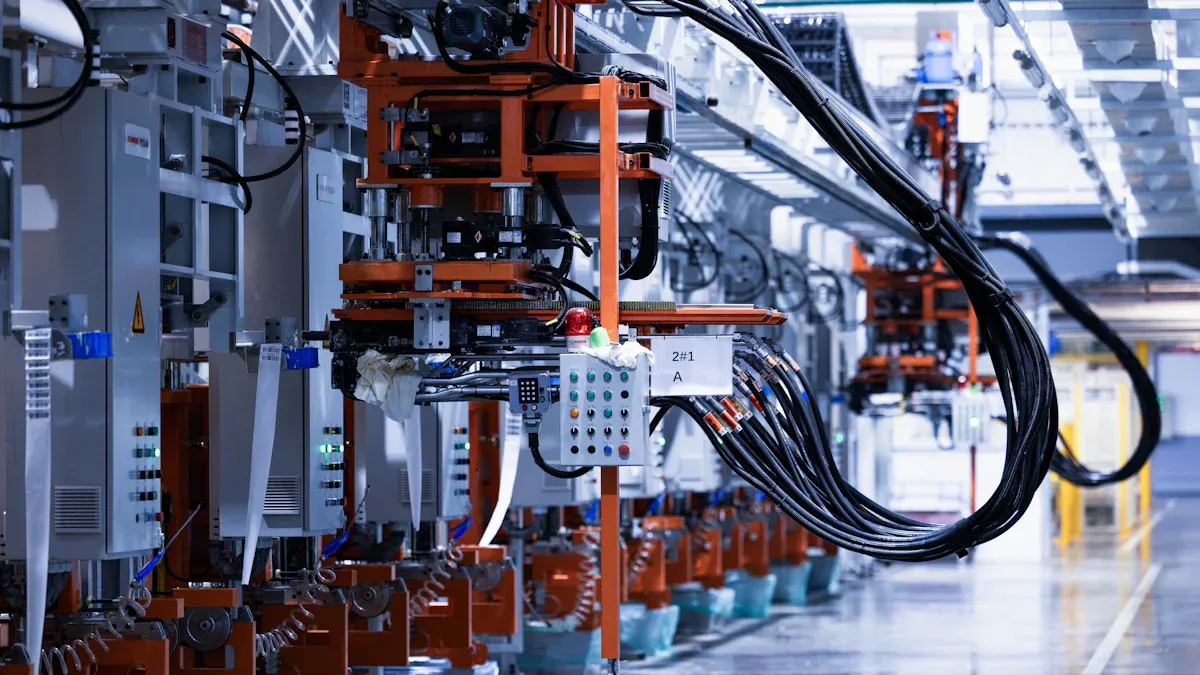

Equipment

The machines your cnc machining service uses matter a lot. Good cnc machining companies buy advanced machines from brands like HAAS, Mazak, DMG MORI, and Komatsu. These machines help you get parts that fit well and look smooth.

HAAS turning centers make parts up to 300mm wide with ±0.005mm accuracy.

Mazak machines can do many jobs and 5-axis machining for tough shapes.

DMG MORI milling centers give high precision for big and small parts.

Komatsu presses do lots of stamping with the same results each time.

Modern cnc machining equipment uses automation, smart controls, and special software. This helps you get better parts, even for custom or small orders. You can trust your cnc machining service to meet strict rules for car, plane, and medical parts.

Tip: Ask your cnc machining service about their machines. Better machines mean higher quality, faster work, and more choices for your project.

Prototyping

Prototyping is an important step in any cnc machining job. You use prototypes to test your design before making lots of parts. A good cnc machining service can make prototypes fast, so you can check if they fit and work well.

How long a prototype takes depends on how hard it is to make. Simple prototypes may only take a few hours. Harder parts can take days or even weeks. Here is a quick guide:

| Prototype Complexity | Typical Turnaround Time |

|---|---|

| Simple Prototype | 4 to 8 hours |

| Medium Complexity | 1 to 3 days |

| Highly Complex | 3 to 6 weeks |

Tongyu can make prototypes quickly, sometimes in just 3–7 days for easy parts. You can use this to test ideas, make changes, and start big orders with confidence. This saves you time and helps you avoid mistakes.

A cnc machining service that is good at prototyping helps you go from design to finished part faster. You can change things quickly and see real results before making lots of parts.

Quality Assurance

Certifications

You should check if your CNC machining provider has the right certificates. These certificates show the company follows strict quality rules. ISO 9001 is very important. It means the company has a strong quality system. This helps you get good parts every time.

Tongyu has ISO 9001 certification. They also have IATF 16949 for cars, AS9100 for planes, and ISO 13485 for medical devices. These certificates show Tongyu meets top standards in each field. You can trust your parts will be safe and made well.

Picking a provider with these certificates lowers your risk of bad parts. It also helps your project follow industry rules.

Inspection

You want your parts to be just right. Inspection makes sure every part matches your design. Tongyu uses special tools and ways to check every detail.

Coordinate Measuring Machines (CMMs) check the size and shape at many spots. This helps Tongyu make sure each part fits your needs.

Optical comparators help the team match part shapes to your drawings. This finds mistakes in the outline.

Surface roughness testers check how smooth each part is. You get the finish you want every time.

First article inspection checks the first part made. In-process inspection checks parts during making. Final inspection checks the last parts before shipping.

Statistical process control (SPC) watches data during making. This helps Tongyu find problems early and fix them fast.

Tongyu keeps digital records for every job. This traceability lets you see all the steps your part took. If you have a question, you can find answers fast. These systems help stop defects before they happen. You get better parts and fewer problems.

Communication & Support

Responsiveness

You need a CNC machining provider who answers your questions quickly. Fast replies show that the company values your time and wants to help you succeed. When you send a request or ask for a quote, you should get a clear answer soon. Good communication helps you avoid mistakes and keeps your project on track.

A responsive team will:

Reply to emails and calls within one business day.

Give you updates about your order status.

Let you know right away if there are any delays or changes.

Explain technical details in simple words.

Quick and clear communication builds trust. You feel more confident when you know what is happening with your parts.

Tongyu’s support team responds fast to your questions. They use email, phone, and online chat so you can reach them in the way that works best for you.

After-Sales Service

After you receive your CNC parts, you may still need help. Strong after-sales service makes your experience better and helps you use your parts with confidence. Many top CNC machining companies offer extra support after delivery.

Here are some ways after-sales service can help you:

You get a clear and easy-to-use catalog of spare parts.

Ordering spare parts is simple, and you can get them quickly.

Dedicated customer support and training help you use your parts the right way.

The company listens to your feedback and works to improve their service.

You can reach support through different channels, like phone, email, or chat.

The company checks in with you after your purchase to make sure you are happy.

They use your feedback to make their support even better.

Good after-sales support keeps your machines running and reduces downtime. You get flexible warranty terms, regular maintenance, and fast technical help. This support protects your investment and helps you work without problems. When you know help is always available, you feel more secure and satisfied with your CNC machining provider.

A provider like Tongyu offers strong after-sales service, so you can focus on your business and trust that your needs will be met every step of the way.

Pricing & Lead Time

Quotation

You want a CNC machining provider who gives you clear and fair prices. Good companies show you how they set their prices. They use different models for different jobs. For example, you might see hourly rates for prototypes or complex parts. For large orders, you often get a price per piece. The table below shows how pricing can change based on your project:

| Pricing Aspect | Details |

|---|---|

| Pricing Models | Hourly rates (prototypes, complex/low volume), per-piece rates (high volume) |

| Hourly Rates | 3-axis: $20-$30/hr; 4-5 axis: $40-$50/hr |

| Per-Part Costs | Simple, small runs: $10-$50/part; Complex, low volume: $160+/part |

| Complexity Impact | More complex parts cost more due to extra time and tools |

| Volume Impact | Higher volume lowers per-part cost |

| Material Influence | Harder materials like titanium cost more |

| Setup & Programming | Setup adds to upfront cost (~$30/hr) |

Tongyu gives you detailed quotes. You see all costs up front, so you can plan your budget.

Delivery

You need to know when your parts will arrive. Lead times depend on order size, part complexity, and where the factory is. In China, most CNC machining orders take 10 to 30 days. Big or complex jobs can take up to 45 days. Some regions, like the Pearl River Delta, finish jobs faster because they have better supply chains.

Tongyu usually delivers prototypes in 3–7 days, low-volume orders in 7–15 days, and mass production in 15–45 days. If you need parts quickly, Tongyu can speed up delivery for urgent orders.

Flexibility

Projects often change. You might need more parts or faster delivery. A flexible CNC machining provider helps you adjust your order. Tongyu can handle urgent requests and changes in volume. You get support if your project grows or if you need to change your design. This flexibility helps you meet deadlines and avoid delays.

Tip: Choose a provider who can adapt to your needs. This keeps your project on track, even when things change.

Reputation & Reviews

When you pick a CNC machining service, reputation is important. A good reputation means the company does quality work. It also means they finish on time and care about customers. You can find out about a company’s reputation by reading what others say. You can also check their past work.

Testimonials

Testimonials are stories from real customers. These stories show if a CNC provider does good work and meets deadlines. When you see good reviews, you feel better about your choice. You also learn how the company fixes problems and keeps promises.

“Tongyu sent our aerospace brackets early. The parts passed all checks. Their team answered every question fast.”

— Aerospace Project Manager

“We needed medical device prototypes with tight tolerances. Tongyu’s team helped us and gave updates at every step.”

— Medical Device Engineer

Testimonials help you see if a provider has done jobs like yours. Good feedback from clients lowers your risk. It helps you make a smart choice.

Here is a table that lists the main things that affect a CNC provider’s reputation:

| Factor Category | Description |

|---|---|

| Quality Assurance | Certifications, regular checks, and fixing mistakes. |

| Technical Capabilities | Advanced machines, tools, and handling hard designs. |

| Customer Service | Fast replies and clear answers. |

| Lead Times | Finishing jobs on time and working quickly. |

| Pricing | Clear prices and good value. |

| Flexibility & Accuracy | Making parts right and changing when needed. |

| References & Testimonials | Good reviews and proof of success. |

References

References let you check how a provider did before. When you ask for references, you can:

Learn if the provider gives good service and is reliable.

See how they did on jobs like yours.

Find out if they care about quality and help over time.

Feel sure the provider can meet your needs.

References and testimonials help you pick a CNC machining partner you can trust. They show real results and help you avoid mistakes that cost money.

Data Security & Scalability

IP Protection

It is very important to keep your ideas safe when you work with a CNC machining provider. You want your intellectual property (IP) to stay protected. Here are some good ways to keep your information safe:

Sign Non-Disclosure Agreements (NDAs): Always use an NDA before sharing drawings or files. A good NDA says what is secret, how long it lasts, and what happens if someone breaks it.

Customize Your NDA: Make sure your NDA fits your project’s needs. Add details about what is protected and who can see it.

Use Strong Contracts: Your contract should say you own your designs. It should also say what happens if someone uses your ideas without asking.

Check Your Provider’s Reputation: Pick a CNC machining company with a good record for keeping customer data safe. Ask about their security steps and how they train workers.

Limit Access: Only share files with people who need them. Use safe ways to send files, like encrypted email or special websites.

Register Your IP: You can register your designs or inventions for extra legal safety.

A trusted CNC machining provider will follow rules like ITAR and DFARS for defense jobs. They use safe file transfers, limit who can see your files, and teach their team to keep your data safe. These steps help you feel sure your ideas will not be stolen or shared.

Future Growth

You want a CNC machining partner who can grow with your business. As you order more, your provider should keep up and not slow you down. Top CNC machining companies buy new machines and smart technology. This helps them make more parts fast and with fewer mistakes.

Providers use advanced CNC machines and Industry 4.0 tools like IoT and data analytics. These tools help control work and find problems early.

Many companies use special software to manage jobs and resources. This cuts downtime and keeps orders on track.

Some providers work with tech partners and schools to find new ideas and train skilled workers.

Here is a table showing how top providers help you grow:

| Provider | Scalability Options | Extra Features |

|---|---|---|

| Hubs | Flexible production volumes | Automated quotes, many materials, tight tolerances |

| Xometry | Small or large orders supported | Fast machining, flexible shipping, big supplier network |

| Protolabs | Volume pricing for big orders | Advanced CNC, tight tolerances, ISO certifications |

When you pick a provider like Tongyu, you can start with a few prototypes and move to mass production as your business grows. You do not need to buy new machines or hire more workers. This helps you save money and stay flexible as your needs change.

Picking the right cnc machining partner takes a few steps. First, look at what machines and tools they use. This helps you know if they can make parts very exact. Next, check if they have certificates like ISO 9001 or AS9100. These show they care about making good parts. Then, compare how much they charge, how fast they work, and if they help after you buy. You should also read what other people say and ask for examples of their work. Make a checklist so you do not forget anything important. If you choose a cnc machining service like Tongyu, you get a team with great machines, strong quality checks, and good results. This makes it easier to find the best cnc machining partner for your job.

FAQ

What information do you need to get a CNC machining quote?

You need to give a 3D drawing. Tell them what material you want. Say how many parts you need. Share the tolerances you need. You can also say if you want a special surface finish. Tell them when you need the parts. This helps the provider give you the right price and time.

How do you know if a CNC provider can handle your material?

Ask the provider for a list of materials they use. Check if they have worked with your metal or plastic before. Some providers, like Tongyu, use aluminum, stainless steel, titanium, brass, PEEK, and more.

Why are certifications important for CNC machining?

Certifications like ISO 9001, AS9100, and ISO 13485 mean the provider follows strict quality rules. You get parts that meet industry standards and pass checks.

Can you order both prototypes and mass production from the same provider?

Yes, you can do both. Many providers, like Tongyu, make small test parts and big orders. You can start with a few parts and order more as your project grows.