Definition and explanation of CNC machining terms

Views: 0 Author: Site Editor Publish Time: 2025-09-12 Origin: Site

Understanding CNC machining terms is crucial for anyone operating a desktop CNC machine or managing a small-scale Stamping Portfolio. From tools to movements, knowing terminology ensures precision, reduces errors, and speeds up production.

Core CNC Components Terms

Spindle

The spindle is a critical component of any CNC machine. It is responsible for rotating the cutting tool at high speeds, which directly impacts the quality of the cut and the overall machining process. The speed of the spindle, measured in revolutions per minute (RPM), is a key factor in determining the cutting quality. Higher RPMs generally allow for faster and smoother cuts, but they also require careful consideration of tool material and workpiece stability to prevent damage or tool breakage. Modern spindles are often equipped with advanced cooling systems to manage the heat generated during high-speed operations, ensuring consistent performance and longevity.

Gantry

The gantry is the structural component that supports and moves the spindle along the X and Y axes. It is typically composed of a rigid frame and rails that guide the spindle’s movement. The gantry’s design and construction are crucial for maintaining precision and stability during machining. High-quality gantries are made from materials that offer strength and minimal deflection, ensuring accurate cuts even over long periods of use. The gantry’s movement is usually controlled by step or servo motors, which provide precise positioning and smooth motion.

Bed

The bed is the foundation of the CNC machine, providing a stable and rigid platform for supporting workpieces or fixtures during machining. It is typically made from heavy-duty materials such as cast iron or steel to ensure stability and minimize vibrations. The bed’s surface is often precision-ground to provide a flat and accurate reference plane for the workpiece. In some CNC machines, the bed may also incorporate features such as T-slots or vacuum systems to secure workpieces more effectively. Proper maintenance of the bed, including regular cleaning and inspection, is essential to ensure consistent machining results.

Collet

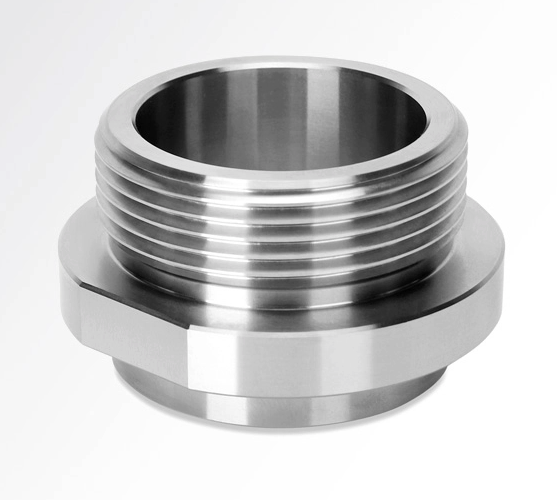

The collet is a crucial component that holds the cutting tool securely inside the spindle. It is designed to provide a tight and precise grip on the tool, ensuring that it remains stable during high-speed rotation. Collets come in various sizes and types to accommodate different tool diameters and materials. Proper selection and installation of the collet are essential for achieving optimal cutting performance and tool longevity. Collets are typically made from high-strength materials such as steel or carbide to withstand the forces and heat generated during machining.

Fixture / Jig

Fixtures and jigs are essential for securing workpieces during machining. They are often custom-made to fit specific workpieces and ensure that they are held in the correct position relative to the cutting tool. Fixtures can range from simple clamps and vises to complex, multi-part systems designed for specific applications. Jigs, on the other hand, are used to guide the cutting tool along a specific path, ensuring consistent and accurate cuts. Both fixtures and jigs are critical for maintaining precision and repeatability in CNC machining, especially when working with complex or delicate parts.

Step Motor / Servo Motor

Step motors and servo motors are the driving forces behind the precise movements of a CNC machine. Step motors are a type of brushless DC motor that moves in discrete steps, allowing for precise control of position and speed. They are commonly used in lower-cost CNC machines and are known for their simplicity and reliability. Servo motors, on the other hand, are more advanced and offer higher precision and faster response times. They are typically used in high-end CNC machines and are capable of handling more complex and demanding applications. Both types of motors are controlled by CNC controllers, which send electrical signals to direct their movements along the X, Y, and Z axes.

Ball Screw

The ball screw is a critical component in converting rotational motion to linear motion with minimal backlash. It consists of a threaded shaft and a nut filled with ball bearings that roll between the threads, reducing friction and increasing efficiency. Ball screws are known for their high precision and smooth operation, making them ideal for CNC machines where accuracy is paramount. They are typically made from high-quality materials such as stainless steel or hardened steel to ensure durability and longevity. Proper lubrication and maintenance of ball screws are essential to prevent wear and ensure consistent performance. The use of ball screws in CNC machines significantly enhances their ability to achieve tight tolerances and produce high-quality machined parts.

Axis & Movement Terms

X-Axis – Left-right movement.

Y-Axis – Front-back movement.

Z-Axis – Up-down, controls depth.

4th / 5th Axis – Rotates or tilts workpiece for complex geometries.

Work Envelope – Maximum reachable area for the cutting tool.

Home Position – Reference point for all CNC movements.

Soft Limits – Software boundaries preventing machine crashes.

Cutting Tools and Bits

| Tool | Function | Notes |

|---|---|---|

| End Mill | Flat-bottom channels | Multi-flute for faster material removal |

| Ball Nose | Rounded tip | Ideal for 3D shapes and contoured surfaces |

| V-Bit | V-carving | Angled cuts, commonly 30°–120° |

| Compression Bit | Laminates / plywood | Combines up-cut and down-cut edges |

| Thread Mill | Internal & external threads | Slow, precise cutting |

| Drag Knife | Vinyl, thin materials | Freely spins with spindle off |

Tip: Choosing the right tool reduces tear-out and improves surface finish, especially on small desktop CNC machine projects.

Cutting & Machining Terms

Feed Rate – Speed of cutter along the material (X/Y axis).

Plunge Rate – Speed of cutter moving down into material (Z-axis).

Depth Per Pass / Step Down – How deep the tool cuts each pass.

Stepover – Horizontal distance between successive passes.

Chipload – Thickness of material removed per tooth per revolution.

Climb Cut – Cutter rotates with the feed, smooth finish.

Conventional Cut – Cutter rotates against the feed, safer for hard materials.

Up-Cut / Down-Cut – Direction of flute rotation affects tear-out and chip clearance.

Pocket Toolpath – Creates cavities.

Profiling Toolpath – Cuts along edges of a design.

Roughing Toolpath – Removes bulk material quickly.

Finishing Toolpath – Smooths surface for final tolerance.

Re-cutting – Occurs when chips are hit again; reduces finish quality.

File and Programming Terms

G-Code – Machine instructions for movements and operations.

M-Code – Machine functions (spindle, coolant, tool change).

Offsets / Work Coordinates – Adjust origin for tool and workpiece alignment.

CAD / CAM – Software for design and toolpath generation.

STL / OBJ / DXF / SVG – Common file formats for CNC machining.

Tip: Accurate file conversion avoids errors when machining small Stamping Portfolio parts on desktop CNC machines.

Measurement and Quality Terms

Tolerance – Permissible dimensional deviation.

Resolution – Smallest detectable movement by the machine.

Surface Finish (Ra) – Smoothness of cut surfaces.

Caliper / Micrometer – Precision measurement tools.

Datum / Origin – Reference point for all measurements.

Kerf – Width of material removed by cutting tool.

Work Hardening – Material hardens as it’s machined.

Automation & Advanced Features

Automatic Tool Changer (ATC) – Switches tools without operator intervention.

Pallet Changer – Allows multiple parts to be loaded automatically.

Live Tooling – Enables secondary operations on lathes.

Digitizers / 3D Scanners – Converts physical objects into digital models.

Observation: These features, even on desktop CNC machines, streamline small-batch Stamping Portfolio projects.

Quick Reference Glossary of CNC Terms

Axis: Plane of motion.

Chipload: Material per tooth per revolution.

Feed Rate / Plunge Rate: Cutter movement speed.

Stepover / Step Down: Horizontal / vertical pass distance.

Spindle RPM: Rotation speed of tool.

Fixture / Jig: Workpiece holding device.

Work Envelope: Max reach of tool.

Toolpath: Predefined route for the cutter.

Climb / Conventional Cut: Cutter rotation relative to feed.

Re-cutting: Avoid to maintain finish and tool life.

Conclusion: Mastering CNC Machining Terms

Understanding CNC machining terms is essential for anyone working with a desktop CNC machine or managing a Stamping Portfolio. Knowing the difference between a climb cut and a conventional cut, or understanding toolpaths and spindle speed, can dramatically improve efficiency, accuracy, and surface finish.

At Tongyu CNC Machining, we provide professional CNC services, high-quality tooling, and expert guidance to help you optimize every project. Whether you are running a small desktop CNC setup or managing larger production tasks, our team can support you in achieving precise results, saving time, and enhancing your workflow.