CNC Machining vs Manual Machining Pros and Cons Explained

Views: 0 Author: Site Editor Publish Time: 2025-07-25 Origin: Site

You may ask what makes CNC machining different from manual machining. CNC machining uses machines that work by themselves. These machines are very fast and very accurate. Manual machining needs people to control the tools. This lets workers make special or custom parts. Today, CNC machining is used much more than manual machining. It makes almost 80% of the money in precision machining. But manual machining is still important for special jobs or small orders. This article will help you look at the good and bad sides of CNC machining and manual machining. It will help you pick what works best for you.

Key Takeaways

CNC machining uses computers to control machines. It makes parts fast and very exact. This is good for big orders and hard designs.

Manual machining needs skilled workers to move tools by hand. It gives more control and is good for small jobs, fixes, or custom parts.

Pick CNC machining if you need high accuracy and fast work. It is also best for jobs that need the same quality every time. Choose manual machining for easy, single, or changeable tasks.

CNC machining saves money on big jobs. It cuts down on waste and needs less work from people. Manual machining costs less at first and works well for small or special jobs.

Many projects use both ways. Start with manual machining for samples or repairs. Then use CNC machining to make many parts.

CNC Machining Overview

What is CNC Machining

CNC machining uses computers to control machines that shape parts. You start with a digital design made in CAD software. The design becomes instructions called G-code. CNC machines read these instructions and move tools on different paths. The tools cut away material to make the part. You do not need to guide the machine by hand. You set up the machine, load the program, and let it run by itself.

Here is a table that lists the main parts of CNC machines and what they do:

| Core Component | Description and Role |

|---|---|

| Input Devices | Let you put programs into the machine. |

| Machine Control Unit | Works like the brain, reading instructions and moving parts. |

| Machine Tool | Holds and moves the cutting tool on X, Y, and Z axes. |

| Driving Mechanism | Moves machine parts with motors and screws for high accuracy. |

| Feedback Mechanism | Uses sensors to check position and speed, fixing mistakes. |

| Display Unit | Shows you the program and machine status. |

CNC machining is known for being very precise and making the same part over and over. You can get very tight tolerances, like ±0.005mm. This is important for things like airplanes and medical tools. Tongyu’s CNC machining services can do CNC turning, multi-axis milling, and sheet metal work. You can pick from many materials, like aluminum, brass, stainless steel, titanium, and plastics such as Delrin and PEEK. Tongyu follows ISO 9001, IATF 16949, AS9100, and ISO 13485 rules, so you get good quality every time.

The steps for how CNC machining works are easy to follow:

Make a CAD model of your part.

Change the design into G-code.

Set up the machine and tools.

Load the program.

Start the machine to cut the part.

Take out and check the finished part.

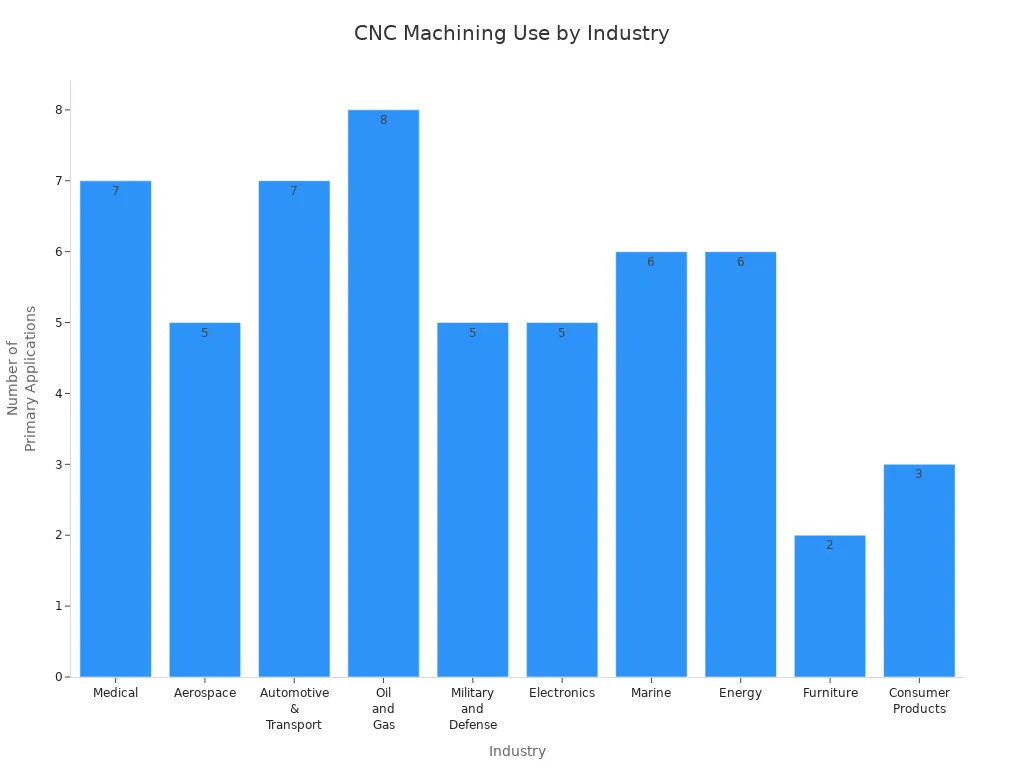

Applications and Industries

CNC machines are used in many industries because they can make detailed and exact parts. CNC machining is used for both small samples and big batches. Here is a table that shows where CNC machining is used and what it makes:

| Industry | Primary CNC Machining Applications and Key Components |

|---|---|

| Medical | Implants, MRI machines, surgical tools, custom devices |

| Aerospace | Airframe parts, turbine blades, satellite components |

| Automotive | Engine parts, brakes, suspension arms, prototypes |

| Oil and Gas | Valves, pistons, drill bits, refinery parts |

| Electronics | Heat sinks, device enclosures, connectors |

| Marine | Propellers, engine parts, corrosion-resistant components |

| Energy | Wind turbine parts, solar panel frames, pump components |

| Furniture | Wood doors, decorative elements |

| Consumer Products | Jewelry, watch parts, custom designs |

Tongyu helps these industries by making things like engine mounts, sensor housings, EV battery parts, flight brackets, UAV parts, and surgical tools. You can use CNC machines for both metal and plastic parts. It works for one sample or thousands of finished products. CNC machining lets you get high quality and fast results in today’s factories.

Manual Machining Overview

What is Manual Machining

Manual machining means you control the machine tools by hand. You use your skill to move the cutting tool and shape the part. This process does not use computers or automation. You decide how fast to cut, where to move, and when to stop. Manual machining uses machines like lathes, mills, and grinders. These machines need you to watch closely and make changes as you work.

If you want to know how manual machining works, you can follow these main steps:

Approve the technical drawings. You check the plans and make sure you understand the size and shape of the part.

Create a model. You might make a sample or a 3D model to see if the design is correct.

Choose the machining technique. You pick if you need milling, drilling, or turning based on the part.

Select the machine tool. You decide which machine fits the job best.

Machine the part. You use your skill to cut and shape the material by hand.

Check quality. You measure the finished part to make sure it meets the requirements.

Manual machining needs a lot of skill. You must pay attention to detail and have steady hands. Your experience helps you make good parts, even if the job is tricky.

Typical Uses

You often use manual machining for special jobs. It works well for simple parts, repairs, and small batches. If you need a quick fix or a custom fit, manual machining gives you flexibility. Skilled machinists can repair broken parts or make new ones when old parts are not available. You can also use manual machining to create prototypes for new designs.

Here are some common uses for manual machining:

Repairing broken or worn parts

Making one-of-a-kind or custom parts

Reverse engineering parts that are no longer made

Producing small batches for testing or special orders

Adjusting oversized or odd-shaped parts that do not fit in CNC machines

Manual machining plays a big role in manufacturing, especially when you need a fast solution or a personal touch. Your skill makes each part unique. You can handle jobs that need careful attention and hands-on work.

CNC Machining vs Manual Machining

Key Differences

When you look at CNC machining and manual machining, you notice big differences. CNC machining uses computers to move the tools. You put in a program, and the machine follows it every time. Manual machining needs you to move the tools by hand. You make changes as you work, using your own skill.

Here is a table that shows how CNC machining and manual machining are different:

| Feature | CNC Machining | Manual Machining |

|---|---|---|

| Setup and Operation | Automated, computer-controlled | Hand-operated, requires skilled machinist |

| Precision and Accuracy | Very high, tight tolerances (±0.001 inches) | Lower, depends on operator (±0.005 inches) |

| Repeatability | Excellent, consistent results | Variable, depends on skill and attention |

| Complexity of Parts | Handles complex, multi-axis designs | Best for simple shapes and features |

| Speed and Throughput | Fast, efficient for large batches | Slower, best for small runs or one-offs |

| Scrap Rate | Low, less waste due to automation | Higher, more chance of human error |

| Cost Efficiency | Lower per-part cost for high volumes | Higher per-part cost for large runs |

CNC machining helps you make parts that are very exact. You can make shapes that are hard to do by hand. Manual machining lets you change things as you go. You need to be skilled to get good results. Manual machining works well for easy jobs or when you want to change things quickly.

Tip: If you need many parts that are all the same, CNC machining is faster and cheaper. If you only need one special part or a quick fix, manual machining gives you more control.

When to Use Each

You should pick CNC machining or manual machining based on your project. Think about how many parts you need, how hard they are to make, your budget, and how fast you need them.

Here are some times when you might use each one:

Use CNC Machining When:

You need parts that are very exact.

Your parts have tricky shapes or need many cuts.

You want to make a lot of parts at once.

You want to save on waste and labor costs.

You must follow strict rules for quality.

Use Manual Machining When:

You only need a few parts or a small job.

Your parts are simple and do not need to be super exact.

You want to change things while you work.

You do not want to pay for programming.

You like having hands-on control.

Many machinists use both ways, depending on the job. For example, you might use manual machining to make a sample part. When the design is ready, you can use CNC machining to make many copies. This way, you get the good parts of both methods.

Here is a table to help you choose:

| Scenario | Best Method |

|---|---|

| High-volume, complex parts | CNC Machining |

| One-off, simple repairs | Manual Machining |

| Tight deadlines, repeat orders | CNC Machining |

| Customization, hands-on changes | Manual Machining |

Always pick the method that fits your project best. If you want speed and accuracy, use CNC machining. If you want to be flexible and work by hand, manual machining is a good choice.

Advantages of CNC Machining

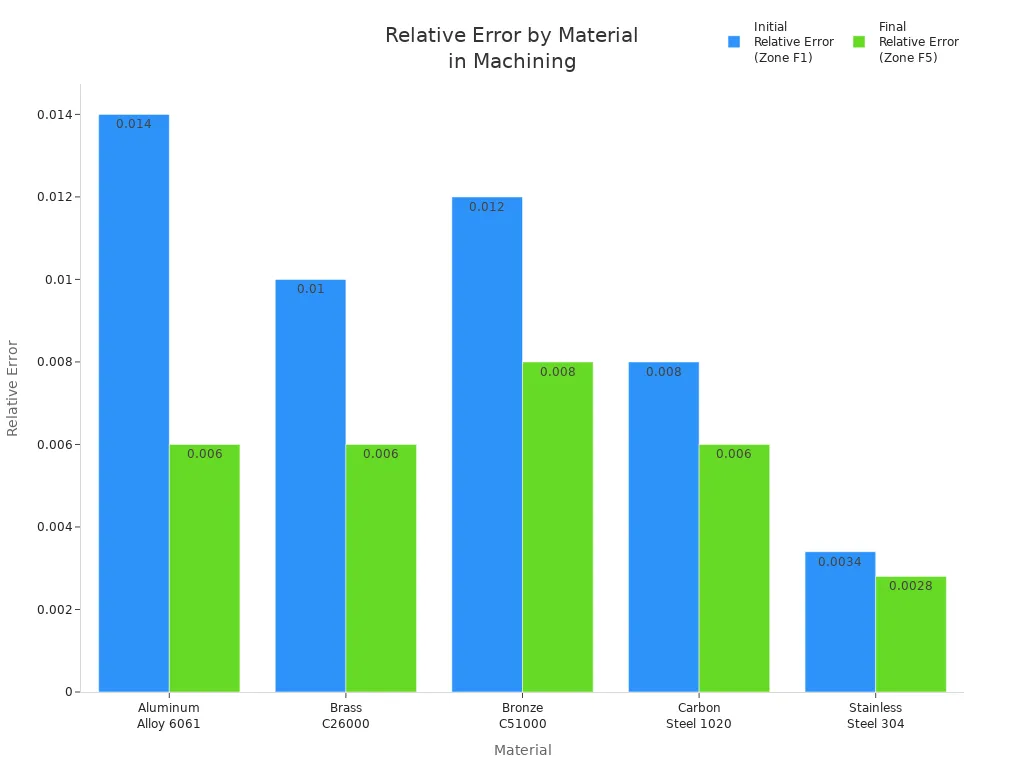

Precision and Consistency

CNC machining makes parts that are very accurate. The computer tells the machine what to do each time. Every part comes out just like the design. You do not have to worry about mistakes from people getting tired. This is a big reason CNC machining is better than manual work.

CNC machining uses feedback systems and controls that work by themselves. These help keep tight tolerances, even for hard shapes. Look at the table below to see how different materials do. The numbers show CNC machining keeps errors low, even with tough materials like stainless steel.

| Material | Initial Relative Error | Final Relative Error | Hardness (HBW) | Machinability (%) |

|---|---|---|---|---|

| Aluminum Alloy 6061 | 0.014 | 0.006 | 95 | 90 |

| Brass C26000 | 0.010 | 0.006 | 70 | 100 |

| Bronze C51000 | 0.012 | 0.008 | 110 | 50 |

| Carbon Steel 1020 Annealed | 0.008 | 0.006 | 126 | 65 |

| Stainless Steel 304 | 0.0034 | 0.0028 | 190 | 45 |

You can count on CNC machining to make the same part every time. Manual machines depend on how skilled the person is. This can cause more mistakes and less matching parts. CNC machining is better when you need parts that must be very exact.

Speed and Efficiency

CNC machining helps you make things faster and easier. These machines can work all day and night with little help. One person can watch many machines at once. This means you need fewer workers and spend less money. You also get your parts done quickly.

Here are some ways CNC machining helps you work faster:

CNC machines can work 24/7, so jobs finish fast.

Multi-axis machines do many steps at once, saving time.

You can change jobs quickly, which helps you make more parts.

There is less waste because the machine follows the program.

The process keeps high accuracy, even for big orders.

Many companies use CNC machining to make lots of parts. For example, Boeing and Tesla use fast CNC machines for airplane and car parts. These machines cut down the time by 25% and skip extra steps. Medical device makers use CNC machining to get smooth, safe parts faster.

Note: CNC machining is the best way to make parts fast and well. You get good quality, speed, and accuracy with every part.

Manual Machining: Advantages and Disadvantages

Flexibility and Adaptability

Manual machining lets you change things as you work. You can fix problems right away if you see them. This is helpful when you need to make special or custom parts. Skilled machinists use their hands and experience to shape each part. This way works well when a project needs extra care or changes.

Here are some ways manual machining helps you be flexible:

You can change what you do while making the part.

You can fix mistakes as soon as they happen.

You can work on repairs or custom jobs without waiting.

You save money on setup for small jobs.

You can handle odd shapes or old parts that need care.

Manual machining is best for making one part or a few parts. You do not need to spend time or money on computer programs. This makes it a good choice for jobs that need quick changes or special attention.

Cost and Labor

Manual machining has both good and bad sides for cost and labor. It costs less for small jobs because you do not pay for programming. The machines also cost less to buy. You spend less on labor for easy jobs. But you need a skilled worker for each machine. That person must watch the machine the whole time.

Here is a table that compares manual machining and CNC machining:

| Aspect | Manual Machining | CNC Machining |

|---|---|---|

| Initial Setup Time | 0.5 to 2 hours (fixturing only) | 2 to 8 hours (programming + fixturing) |

| First Part Speed | Faster for simple parts | Slower due to program testing |

| Production Speed | Linear increase with each part | Up to 4 times faster after setup |

| Tool Change Time | Manual, 3-5 minutes | Automatic, 10-30 seconds |

| Equipment Cost | $3,000 to $25,000 | $5,000 to $200,000 |

| Hourly Operating Cost | Approximately $40/hour | Approximately $80/hour (3-axis machine) |

| Programming Cost | None | $50 to $150/hour |

| Labor Requirements | One skilled operator per machine | One operator can manage multiple machines |

| Material Waste | 15-25% | 5-10% |

| Cost-effectiveness | Better for small runs (1-10 parts) | Better for larger runs (above 10-15 parts) |

Manual machining depends on how skilled the worker is. Many people start learning machining by using manual machines. You learn to measure, set up, and make parts by hand. This helps you if you want to learn CNC machining later. Many jobs want workers who know both ways.

Manual machining gives you control and lets you change things. But you must watch out for mistakes and always have a skilled worker. For small jobs, you save money and get fast results. For big jobs, CNC machining might work better.

Choosing the Right Method

Project Requirements

When you pick between CNC machining and manual machining, start with your project needs. Think about how exact your parts must be. Some jobs, like in aerospace or medical fields, need very tight tolerances. CNC machining is good for this because it is very accurate. The machine makes each part the same every time.

If your parts have tricky shapes or need many cuts, CNC machining is best. The computer controls the machine, so results do not change. For simple parts or repairs, manual machining is more flexible. You can change things as you work and fix problems fast.

You should also think about how quickly you need your parts. CNC machines can work all day and night. This helps when you have a short deadline. Manual machining is slower because you do each step by hand.

Tip: Pick CNC machining if you need high accuracy, tricky shapes, or fast results. For small jobs or custom work, manual machining gives you more control.

Volume and Budget

How many parts you need and your budget are important too. CNC machining costs more at first. You pay more for the machine and for programming. But if you make lots of parts, CNC machining saves money over time. It needs less labor, so you spend less later.

Manual machining costs less to start. The machines are cheaper, and you do not pay for programming. This is good for small batches or test parts. You spend less at first, but it takes longer and needs skilled workers.

Here is a table to help you compare:

| Factor | CNC Machining | Manual Machining |

|---|---|---|

| Initial Investment | High ($20,000–$100,000+) | Low ($1,000–$10,000) |

| Labor Costs | Lower over time | Higher (skilled operator needed) |

| Cost Effectiveness | Best for large volumes | Best for small runs or prototypes |

| Efficiency | High, runs 24/7 | Lower, slower process |

| Flexibility | Less flexible for quick changes | Highly flexible |

If you do not have much money and only need a few parts, manual machining is a good choice. If you want to make many parts, CNC machining is better for saving money in the long run, even though it costs more at first.

Real-World Scenarios

Prototyping

Before making lots of parts, you need to make a prototype. Both CNC machining and manual machining help you test ideas fast. CNC machining can turn a digital design into a real part quickly. You can check if the part fits and works well with high accuracy. Manual machining is good for making just one sample or when you want to change things by hand.

Here is a table that shows how different industries use both methods for prototypes:

| Industry | Example Prototypes | Materials Used | Purpose/Benefit |

|---|---|---|---|

| Consumer Products | Smartphone cases, power tool housings | ABS plastic, polycarbonate | Ergonomics and assembly testing |

| Medical | Surgical instruments, orthotic devices | Stainless steel, specialty alloys | High precision, functional testing |

| Industrial | Gears, brackets, robotic parts | Aluminum, nylon, hardened steels | Moving assemblies, functional tests |

| Aerospace | Wing ribs, engine components | Aluminum, titanium, Inconel | Exact fit, flight testing |

| Automotive | Brake calipers, transmission housings | Hardened steels, aluminum | Fit and function, tooling prototypes |

CNC machining is fast and makes the same part every time. Manual machining lets you make special shapes or creative designs. You can pick the best way for your project.

Mass Production

When you go from making one part to many, CNC machining is best. You can program the machine to make thousands of the same part. This way, you get high accuracy and fewer mistakes. It saves time and money for big jobs.

Here is a quick table to compare:

| Aspect | CNC Machining Advantages | Manual Machining Advantages |

|---|---|---|

| Setup Time | Automated, repeatable tasks | Minimal setup for small batches |

| Labor Demand | One operator can run several machines | Direct hands-on control |

| Cost | Lower labor cost for big runs | Low cost for very small batches |

| Precision | Consistent quality across all parts | Flexible for custom jobs |

CNC machining takes longer to set up at first. But it is faster and better for big orders. Manual machining is good for small jobs or when you need to change each part.

Tip: If you need lots of parts, CNC machining helps you save money and get good quality.

Custom Parts

Sometimes you need a special part for a project or repair. CNC machining is great when you want very exact parts or tricky shapes. These machines can cut, mill, or drill almost any material. Many companies use CNC machining for custom tools, medical parts, and car parts. CNC machines help you set up faster and make fewer mistakes.

Manual machining is still useful for custom work. If you need just one part or want to change things as you go, manual machining gives you control. Skilled machinists can fix or adjust parts while working, which is good for special jobs.

Recent studies show CNC machining can make custom parts 30% faster and 15% more accurate. You also get smoother surfaces and fewer errors. Companies that use CNC machining for custom parts finish jobs quicker and spend less money.

CNC machining makes parts very exact and quick. The quality stays the same for each part. You finish jobs faster and throw away less material. This is best for big projects or hard shapes. Manual machining is cheaper to start. You can change parts while you work. It is good for small jobs or fixing things.

Use CNC machining if you need very exact parts, lots of pieces, or tricky designs. Use manual machining for easy, special, or just a few parts. Always pick the way that fits your project, money, and what you want to do.

FAQ

What is the main benefit of CNC machining?

You get high precision and repeatability. CNC machines follow digital instructions, so every part matches your design. This helps you make complex shapes and keep tight tolerances.

When should you choose manual machining?

You should pick manual machining for small jobs, repairs, or custom parts. It works best when you want to change things quickly or need only a few pieces.

Can you use both CNC and manual machining for one project?

Yes! You can use manual machining to make a prototype or fix a part. Then, you can switch to CNC machining for mass production. This gives you flexibility and speed.

What materials can CNC machines handle?

CNC machines work with many materials. You can use metals like aluminum, steel, and titanium. You can also use plastics such as Delrin and PEEK.

How do you decide which method saves more money?

Tip: For large batches, CNC machining saves you money over time. For small runs or one-off parts, manual machining costs less up front.